Grabbed Diaphragm Wall

To complete a construction site successfully today, high demands are placed on efficiency and cost-effectiveness. The DHG (Diaphragm Hydraulic Grab) can meet these requirements. Its advantages over a mechanical grab lie in the high degree of trench verticality as well as easier handling. Due to its high closing forces, its freefall capacity, as well as the wide range of possible configurations, the hydraulic diaphragm wall grab is capable of dealing with a large variety of applications and challenges faced by our customers worldwide.

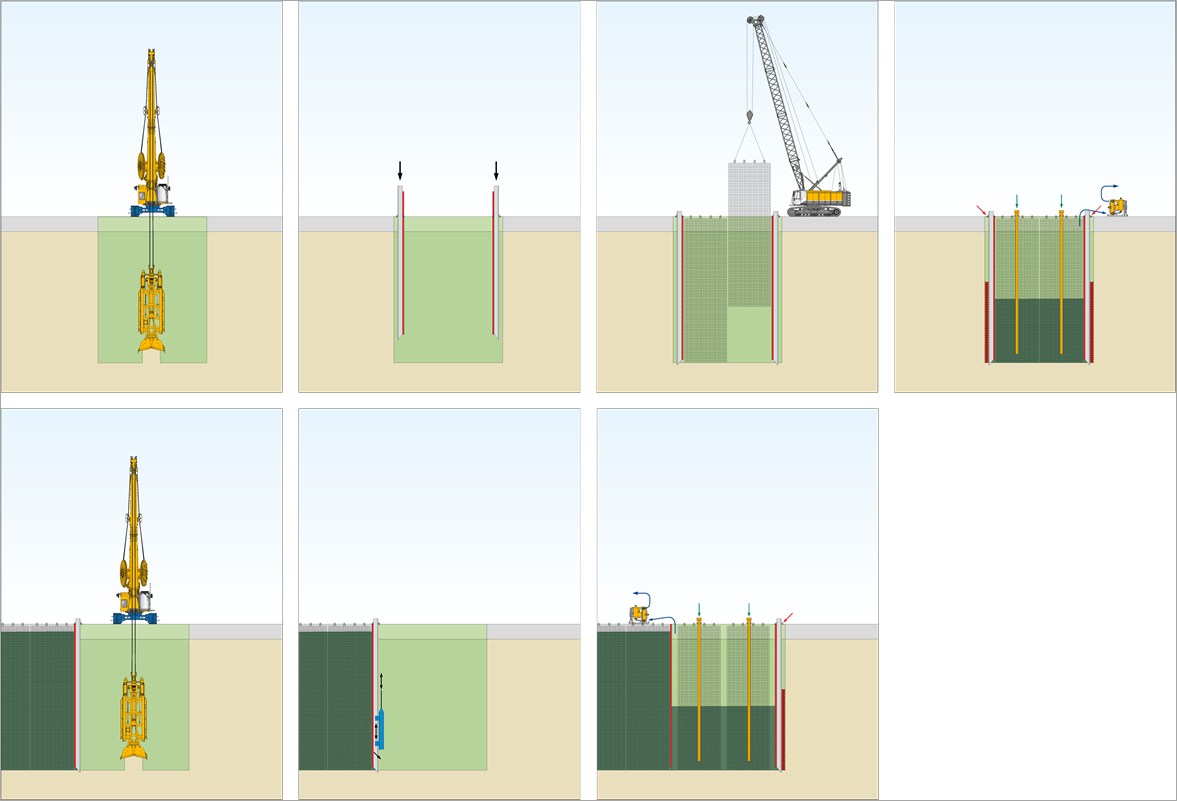

With the DHG (Diaphragm Hydraulic Grab) technique, trench excavation is carried out in stages. The first stage consists of inserting the grab into the trench, loosening and excavating the soil at the base and removing the excavated spoil material from the trench. The open trench is stabilized by a support slurry. On completion of the trench excavation, joint sections, such as stop-ends, and reinforcing cages are inserted into the trench, which is concreted in a further stage. The support slurry, which is displaced by the concrete, passes through a desanding plant and is then pumped back into the slurry circulation system for reuse in the trench.