Separation Technology

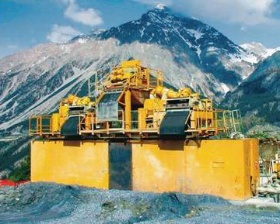

Desanding plants are employed to remove soil particles in drilling muds and support slurries used in foundation engineering. They can be either water-bentonite, water-polymer, or water-cement and bentonite suspensions. Desanding plants have further applications in gravel pits, in the mining industry and in micro-tunneling projects. The regeneration or cleaning capacity of a desanding plant is determined by the plant´s intake capacity of contaminated suspension. It is defined in m3/h. The regeneration efficiency or the “significant cut-off point” d50 indicates the smallest particle size of which at least 50 % can be removed from a suspension. It is expressed in 1/1000 mm or micron.

Type |

Capacity |

Inst. power |

Cyclones |

Cut-off point d50 |

|---|---|---|---|---|

BE 100-60 LBE 100-60 |

100 m³/h

100 m³/h |

19.3 kW

24 kW |

12 ”

15 “ |

0.060 mm

0.060 mm |

| BE 250-60 | 250 m³/h | 59 kW | 18 “ | 0.060 mm |

| BE 170-60 | 170 m³/h | 32.2 kW | 15 “ | 0.060 mm |

| BE 275-60 | 275 m³/h | 69 kW | 1 x 18 “ | 0.060 mm |

| BE 425-60 | 425 m³/h | 89 kW | 2 x 18 “ | 0.060 mm |

The main components of all desanding plants are:

- coarse screen for intercepting stones larger than 5 mm

- storage tank of the coarse screen cyclone with

- cyclone feeder pump for removing fine particles from the suspension

- dewatering screens for abstracting further water from

the solids discharged by the cyclone

Desilter

Type |

Capacity |

Cyclones |

Cut-off point d50 |

|---|---|---|---|

| BDS 125-30 K

BDS 250-30 K |

125 m³/h

250 m³/h |

3 x 6 ”

6 x 6 “ |

0.030 mm

0.030 mm |

| BDS 125-20

BDS 250-20 |

125 m³/h

250 m³/h |

6 x 4 ”

12 x 4 |

0.020 mm

0.020 mm |

| BDS 85-20 K

BDS 125-20 K BDS 250-20 K |

85 m³/h

125 m³/h 250 m³/h |

4 x 4 ”

6 x 4 ” 12 x 4 “ |

0.020 mm

0.020 mm 0.020 mm |

Decanter Centrifuge

| Technical specifications | |

|---|---|

| Power rating (kW) | 75 |

| Capacity max. (m³/h) | 90 |

| Weight approx. (t) | 12.5 |